The renowned Liechtenstein company UT Umwelt- und Transporttechnik AG has built on a far-reaching solution for the future with the renovation of its heating system. An energy-saving system from infrared heating specialist KÜBLER was installed. Since 2012, this solution has reliably ensured sustainable energy and CO2-reduced heating operation.

The heating problem

Crane runway and heaters on a hall ceiling? In 1987, the dark radiators in the Ruggell assembly hall were placed at a height of 3 to 4 m directly above the workstations for fear of collisions and no exhaust gas routing was installed. In the meantime, the appliances had become outdated, spare parts were no longer available and completely new environmental protection and energy efficiency requirements had come into force. Modernization of the heating system was urgently needed.

The customer requirements

- Modern technology that meets legal requirements for years to come

- Solution to the heating / crane runway collision problem

- High reliability

- Simple operation, quick setting changes

- Reliable spare parts supply

The solution

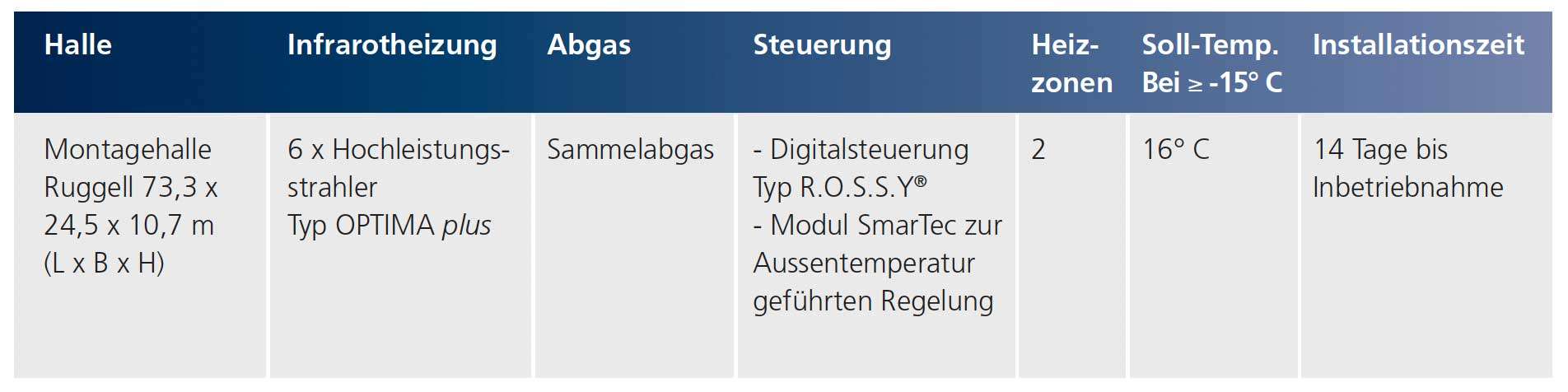

According to the old model of workplace heating, exhaust gas routing was not feasible. If only because of the crane runway. Therefore, the recommendation of Ospelt Haustechnik AG from Vaduz was followed. UT implemented the KÜBLER concept for the overall heating of the hall. This solution provided for the suspension of highly efficient infrared radiators - on the hall ceiling between the lighting and the crane. Centrally controlled by a modern and easy-to-operate digital control system.

The challenges

The entire system was completed within 14 days. A challenge, as the assembly work had to be carried out during ongoing operations. The conditions were also difficult: The prestressed concrete ceiling barely allowed any holes to be drilled for the suspension of the infrared heaters. Everyone involved in the project - UT, Ospelt, the architect at the time, a structural engineering office, fastening specialists from HILTI and KÜBLER - worked together. Together, an ideal fastening solution was found. The extensive dismantling and reinstallation of the entire electrical system by UT itself was also completed quickly and according to plan.

"We have invested in pioneering technology in terms of energy efficiency".

"I would hardly have thought it possible for the collaboration with a non-local company to work so smoothly."

Walter Rohrer, Ospelt Haustechnik AG

The result

"Saving energy was not a priority for us. But 29 % reduced CO2-taxes and energy costs*," says Edi Veith, Technical Director at UT. "We are happy to have made this decision." Walter Rohrer from Ospelt sums up his impressions as "simply excellent", referring to the overall functionality of the new hall heating system. However, both the client and the building technician were particularly impressed by the excellent cooperation and coordination during the implementation phase. "We're used to other things," says Walter Rohrer. The system is now in its third year of reliable operation. In terms of environmental requirements and energy efficiency, the company is legally on the safe side for years to come. And the feedback from employees has also been very positive. "There are no discussions. On the contrary, the working atmosphere is perceived as very pleasant," says Edi Veith. UT is also very satisfied with the control system. Guido Ritter from UT: "Thanks to the simple central control system, we can control the heating process in a targeted manner so that the water in the hall doesn't freeze as it used to."

* Average savings p. a.: 29.24 % (calculated from the consumption values of the old system 2007 - 2011 compared to the consumption values after the refurbishment 2012 - 2014).