mateco AG is one of the leading providers in the rental of modern access technology. With over 2200 devices in more than 200 different versions, the product range offers solutions for every access problem. Founded in 1973, the company is active throughout Europe. In Germany alone, it employs around 250 people at 17 locations. The Mannheim branch has been serving the second largest industrial site in Baden-Württemberg since 1989 and is of central importance to the company.

One of the most modern hall heating systems went into operation at the Mannheim branch of mateco AG. The ambitious modernization project replaces the previous hot air heating system, which was fed by district heating, and takes a leading position in terms of technology and efficiency. For the first time, the entire heating control system was outsourced as part of the modernization. The decision in favor of the innovative overall concept from Ludwigshafen-based KÜBLER GmbH will bring mateco AG energy savings of around 70% and is a pioneering contribution to environmental protection and sustainability.

The project

Since 1989, the warehouse and workshop at mateco AG Stuttgart's Mannheim site had been heated by a 400 kW hot water-operated hot air system fed by district heating. In autumn 2005, the contract to modernize the heating system for the 17,900 m3 and 1,922 m2 building to KÜBLER GmbH.

The task

The reason for the redesign of the heating solution was the decommissioning of the public district heating network. In addition to decoupling from the public grid and replacing the existing hot-air heating system, the modernization measures focused in particular on achieving savings in primary energy consumption. The building, which was constructed in 1989, has modern insulation. Due to its good general condition, the forecasts for potential savings were cautious. 30 to 40% were the expectations.

The energy modernization measures

The modernization concept comprises a series of individual measures. Specifically, the following steps were implemented:

To reduce heating energy consumption:

- Replacement of the existing hot air heating system with an energy-saving infrared heating system. Eight Optima infrared systems were used. A total installed output of over 300 kW. The heating principle of the high-performance systems from KÜBLER is similar to that of natural solar radiation. It is not the air that is heated but the objects in the room as well as the floor and walls. The entire storage mass of the building is thus used for heat transfer. The modern infrared systems heat dust-free and draught-free, require only short heat-up times and are controlled separately according to three heating zones depending on the usage profile and current heat requirement in the hall.

- Outdoor temperature-independent control for optimized heating activation. The resource-optimizing control system R.O.S.S.Y® not only serves to conveniently control the heating systems, but also leads to significant reductions in energy, maintenance and spare parts costs. In addition, the system, which has been awarded the Innovation Prize of the Federal Ministry of Economics, is also the basis for modern service products such as remote control.

- Optimization of the processes for demand-based control of the heating. The entire heating system is controlled from the KÜBLER headquarters in Ludwigshafen. Outsourcing the heating process not only frees up new room for maneuver at the mateco branch in Mannheim, but also guarantees that the heating is controlled at a sustainably optimal level. Within the framework of organized processes, this ensures cost and energy-saving operation according to the premise "heat as much as necessary - not as much as possible". This also means that there is no more unnecessary heating in Mannheim on public vacations and vacation days.

To reduce energy consumption for water heating:

Installation of a new condensing boiler for water treatment in the office and social wing.

To reduce electricity consumption in the heating sector:

Infrared technology eliminates the need for expensive fans to distribute the warm air into the working area and pumps to transport the heating medium.

The results

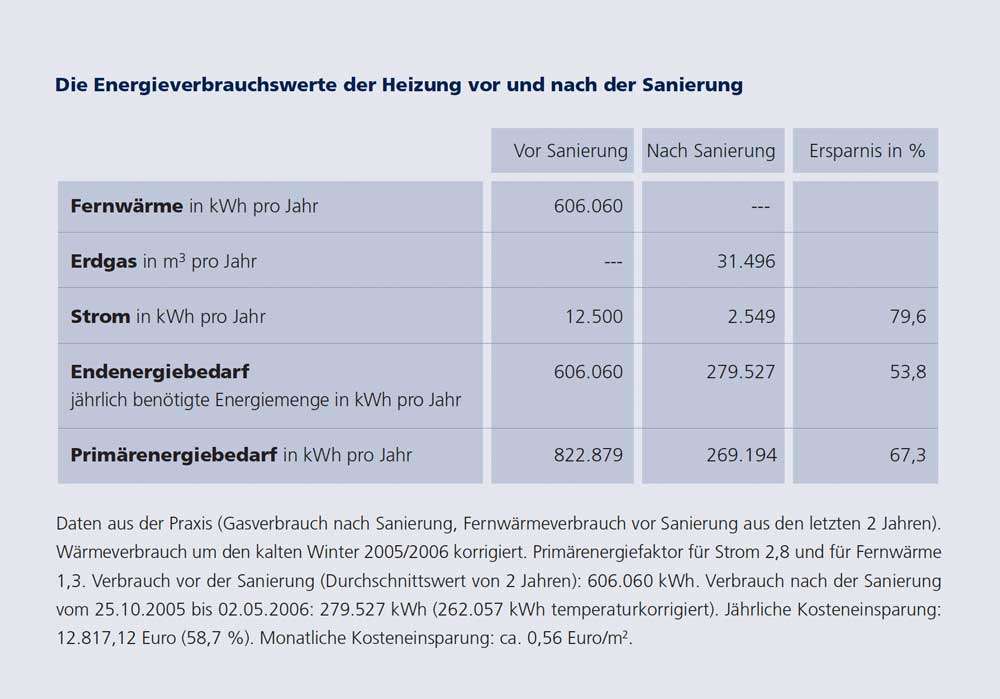

The networking of all components from system planning, installation and maintenance to process control posed particular challenges for the Ludwigshafen-based hall heating specialist. Nevertheless, the entire project was put into operation on schedule. The results at the end of the first heating period exceeded expectations: the actual

Hans-Peter Kauderer is the founder and now Deputy Chairman of the Supervisory Board of mateco AG. His decision to completely outsource process management made the pilot project for the new heating strategy W.I.N.E. possible. Our editorial team spoke to him in Mannheim.

You have implemented an ultra-modern heating concept in Mannheim. What did you expect from it?

After the public district heating system was shut down, we needed a new heating system. Of course, we expected a new system to be more modern, more convenient and more efficient than the old one. But we wanted something more. Our company philosophy is based on sustainability. The solution had to be future-proof in the long term and use energy reserves sparingly, both ecologically and economically.

Why did you choose a KÜBLER system? We were clearly convinced by the advice. You don't deal with heating technology every day. Especially at the beginning, there was a lot of uncertainty about the advantages and disadvantages of the various technologies. KÜBLER gave us an excellent overview of the systems available on the market. Completely non-binding. Backed up with all comparative and profitability calculations through to public funding programs. This has created a high level of trust. In the technology on the one hand, and in the implementation on the other.

In Mannheim, an overall concept comprising heating, control and outsourcing of process management was implemented for the first time. What prompted you to do this?

Continuous and professional control support, no need to study the control instructions, no incorrect operation by untrained personnel, fast response times, all from a single source. And the most important thing: of course the savings potential that we expected from outsourcing. As the figures show, this calculation worked out perfectly for us.

What did the modernization measures mean for ongoing operations?

There were no process disruptions that were not planned. The project was consistently organized and excellently supervised. It was installed in one go. Thanks to the simple installation and modular concept of the system together with the access technology from mateco AG, we had no problems at all during operation.

What is the response from employees? Are there differences in heating comfort?

The system is quiet to noiseless, disruptive air movements are a thing of the past, machines and systems have a pleasant working temperature. Well-being in the workplace has been significantly improved. Now our company has to learn how to deal with the new heating comfort. This means, for example, that appropriate clothing is required. The days when you had to wear T-shirts in the storerooms even in winter because the heat could not be regulated are over in Mannheim.

Have your expectations been met?

The forecast expectations were exceeded. With the savings achieved, the investment virtually pays for itself. Using the best and most modern technology is therefore not a question of luxury. For us, this is a reason to focus more intensively on the topic of heat in other buildings and systems. For us, the Mannheim site is a benchmark for further investments in heating systems and certainly sets an example for every other company that wants to heat its halls today.

About KÜBLER

With its innovative infrared systems, KÜBLER GmbH develops and sells cutting-edge technologies for energy-efficient hall heating. As a full-service provider of turnkey solutions, the company offers a comprehensive product range for a wide variety of hall types and room environments. KÜBLER has made a significant contribution to the breakthrough of modern infrared heating systems in Germany and has been an important driving force and trendsetter in this technology for over 20 years.

KÜBLER regularly receives awards for its innovative achievements. The national and international awards include the Federal Prize for Outstanding Innovative Achievements from the Ministry of Economic Affairs in 2004, the Bavarian State Prize in 2006, the Innovation Prize from the state of Rhineland-Palatinate in 2012 and the German Sustainability Award. KÜBLER received the highest German award for sustainable entrepreneurship in the category "Germany's most sustainable product" for the special energy efficiency of the H.Y.B.R.I.D. system.

Founded in 1989, the company employs over 100 people and is one of the top companies in the industry in Europe with locations in Ludwigshafen, Dresden, Hagen, Hamburg, Ingolstadt, Prague (Czech Republic), Fegyvernek (Hungary), numerous foreign agencies and a nationwide service network.