Anyone entering the Eiffel Deutschland Stahltechnologie factory premises in Hanover for the first time will inevitably gain a new sense of scale. Production halls and office buildings extend over a huge area of 53,000 m². Everything that is manufactured here is gigantic: steel components for bridge structures, building construction projects, power station buildings, hydraulic engineering or conveyor technology. There is a precision in these giants that has made the traditional company one of the world's few experts in steel construction. Buildings such as the Pompidou Center (Paris), the Olympic Stadium (Munich) and the World Cup stadium in Durban speak for the company's international reputation. The company generates an annual turnover of 90 million euros.

In the middle of the crisis year 2009, Eiffel Deutschland Stahltechnologie commissioned the renewal of the entire hall and office heating system at the Hanover site, an investment volume of 600,000 euros. H.Y.B.R.I.D. was installed for the first time on this scale. After the first heating period, the cash flow had improved by 200,000 euros.

But it is not only because of the improved liquidity that Eiffel is glad to have invested at the right end despite the global economic crisis. The risk of a complete breakdown of the old system had become too high - the investment for improvised repairs would have been of no lasting value. That too could now be saved. The comprehensive modernization project in Hanover shows how important it can be from a business point of view to invest in modern energy-saving technology, especially during a recession. To save considerable amounts of CO2-emissions - and as one of the most important measures for sustainably reducing consumption and fixed costs in a crisis.

The project: 17,292 m² uninsulated into the winter

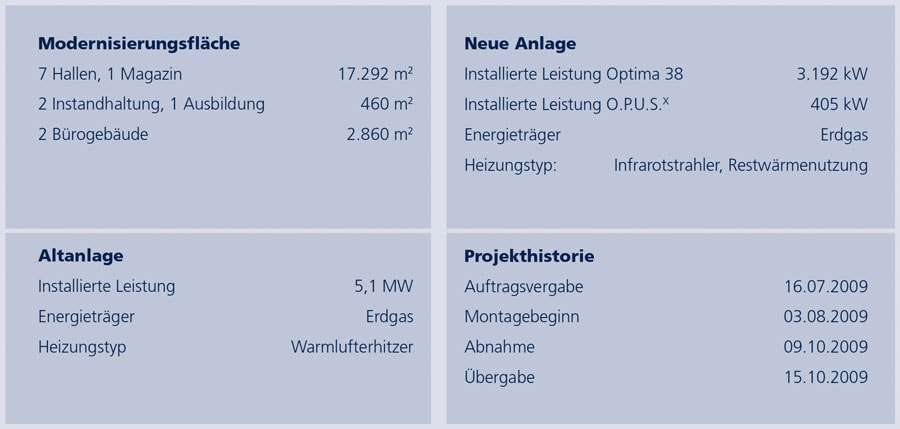

The approximately 100-year-old production halls on the Eiffel Deutschland Stahltechnologie company premises in the Brinker Hafen industrial estate were originally designed purely as weather protection. In the 1960s, the building structure was extensively expanded and both main buildings were equipped with a 1,500 kW heating system fired by two boilers and the first hot air heaters were installed in the halls. Further extensions and additions to the hot air heating system followed in the 70s, 80s and 90s. When the decision to modernize the heating system was made in spring 2008, a total of 17 individually controllable hot air heaters with a total output of 5.1 MW were in operation to heat 7 halls with a total area of 17,292 m², 460 m² of training workshop plus maintenance and 2,860 m² of office space.

The task: 40 % less costs, 100 % more comfort

Eiffel was incurring around 400,000 euros a year in heating costs. This enormous sum was the main motivation to look for a new heating system. The aim was to save at least 40 percent in primary energy consumption. At the same time, they wanted to get a second problem under control: The old hot air heating systems each had to be controlled individually - an almost sporting undertaking given the size of the company premises. The control system for the new heating system needed to be intuitive and, above all, easy to operate from a control station.

The solution: the hall heating system that also heats offices

Initially, the task concentrated exclusively on heating the production halls. However, with the product launch of H.Y.B.R.I.D. in 2009, the focus expanded: the high additional savings potential on the one hand and the prospect of completing two refurbishment projects in one step made the simultaneous modernization of the office heating systems interesting. When the project was signed on July 16, 2009, the scope of the order included an additional 3,320 m² of space to be heated through the use of residual heat, including office buildings as well as the training workshop and maintenance.

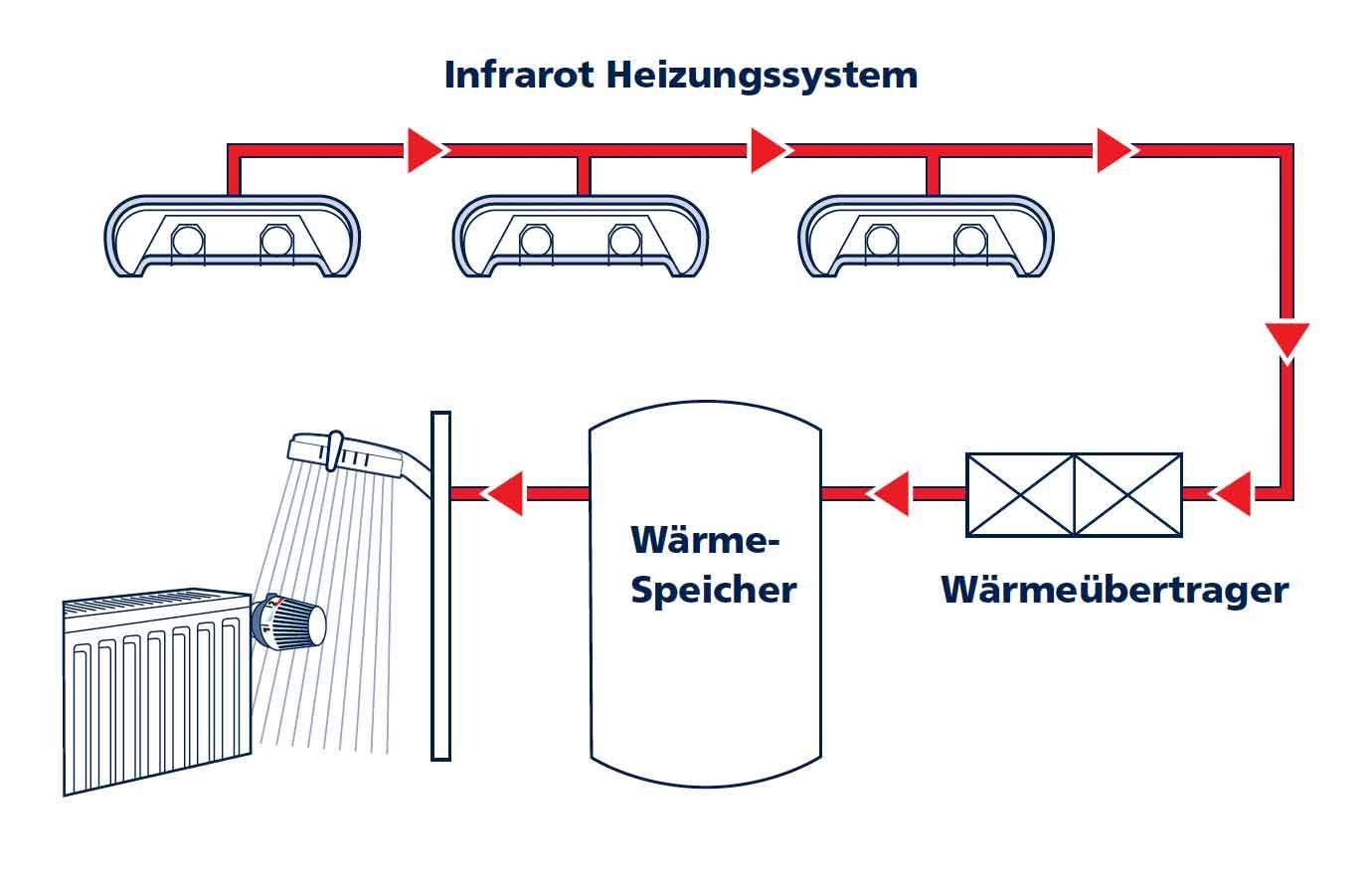

The energy-saving measure: three components - one hybrid system

High-performance heating systems with a maximized infrared component were used. The remaining energy that cannot be used to heat the hall with infrared and was previously lost via the exhaust air is recovered through the innovative use of residual heat for hot water preparation. This means that the energy used for heating can be used almost completely - an optimal use of energy for Eiffel. The H.Y.B.R.I.D. components in detail:

The Optima high-performance infrared system

A total of 84 Optima 38 units with a total output of 3,192 kW were installed. The design guarantees very pleasant, even, dust-free and draught-free heat distribution at 14 °C during the cold periods - regardless of the outside temperatures. With its short heating-up times and efficiency-optimized design, the high-performance Optima series stands for the most powerful and at the same time most efficient infrared heaters from KÜBLER.

The residual heat utilization O.P.U.S.X

During the winter months, the hot water supply for the training workshop and both buildings used for maintenance is now provided almost entirely by using residual heat from the exhaust gas flow of the infrared heaters. For this purpose, 6 units of the newly developed O.P.U.S.X heat exchanger system from KÜBLER with a total output of 405 kW were installed and connected to the existing pump hot water heating networks. The system provides up to 15 percent additional energy for the hydraulic heating systems - and at virtually no cost.

The R.O.S.S.Y® digital control unit

The latest generation of the resource-optimizing R.O.S.S.Y® control system from KÜBLER regulates the entire heating system at Eiffel. In accordance with the different usage profiles of the milling, cutting, assembly and welding departments, the halls were divided into 18 heating zones, each of which can be individually controlled as required. R.O.S.S.Y®* stands for a high level of operating convenience and a significant increase in efficiency. By optimizing the switch-on and switch-off times and the temperature curve alone, up to 20 % of primary energy can be saved.

* R.O.S.S.Y®, the resource-optimizing control system from KÜBLER, was awarded the Innovation Prize of the Federal Ministry of Economics in 2004.

The result: enthusiasm in every respect

The hybrid system was handed over on time on October 15. This means that the first heating period 2009 / 2010 has already been fully utilized. The results of the modernization project exceed expectations in every respect.

Costs and savings

At 367,339 m³, the gas consumption of the heating systems is 50 percent lower than the previous year - a saving of around 200,000 euros.

However, the actual savings are likely to be much higher if the following aspects are taken into account:

- adjustment for the different weather conditions in the winter of 2008 compared to the long and cold winter of 2009

- the reduction of electricity costs by approx. 20,000 euros

- The heating comfort has improved significantly with regard to the warm room setting and lack of draughts:

- There are no more cold areas

- the temperature level was raised even under extreme conditions and the required temperatures were achieved

Environmental protection and legislation The energy savings achieved at Eiffel have a direct impact on the level of pollutant emissions. The optimized use of energy reduces CO2-emissions by 50 percent compared to the values of the old system.

Indoor climate and sick leave

Due to the high temperatures in the direct vicinity of the ovens, the employees' clothing was correspondingly light in the winter months. The result was a relatively high sickness rate due to the high temperature delta away from the ovens. The uniform room climate, especially the lack of draughts and the consistently warm hall floor were quickly perceived as very pleasant after a short period of acclimatization - the sickness rate was reduced.

Ease of use and optimized driving style

The switch to the digital resource-optimized control system R.O.S.S.Y® was practically done at the touch of a button. At Eiffel, the entire hybrid system is now controlled via a simple Windows interface - from a single, freely definable PC workstation. For this reason alone, the added convenience for those responsible is enormous. The setting parameters offer a wide range of options - from weekend and public holiday control to optimization of the heating times in relation to the respective outside temperature. By optimizing heating operation in this way, R.O.S.S.Y® makes a major contribution to the cost-effectiveness of the overall system. After all, even with Eiffel, the most energy-efficient heating system is the one that is not running.

Results

Customer interview with Antonio De Lazzari, Eiffel Germany Steel Technology

The successful implementation of a major project requires a team with a great deal of experience in system integration. However, the tight schedule and the success of the modernization measure would not have been possible without the constructive cooperation with the responsible persons and employees at Eiffel. This made it possible for the modernization to be implemented during the ongoing production process without any major disruptions. Antonio De Lazzari, Head of Maintenance at Eiffel Deutschland Stahltechnologie, was in charge of the project from the tender to commissioning. Our editorial team spoke to him about his experiences.

You don't make a decision about a modernization project of this magnitude overnight. How did it come about?

With our old heating system, we were burning up roughly the value of two very well-equipped detached houses every year. The modernization was long overdue and actually planned for 2008, but then had to be postponed. Given the amount of savings we have now, it's really annoying that we couldn't take the previous year with us. On the other hand, there was no H.Y.B.R.I.D. in 2008.

You mention H.Y.B.R.I.D.: why did you choose the new KÜBLER system?

Originally, we were only interested in modernizing the hall heating systems. We already knew at the time that the office heating systems would also be due at some point. But for us, these were two different construction sites. When KÜBLER introduced H.Y.B.R.I.D., it opened up completely new possibilities for us. We were able to realize both projects elegantly in one step. That alone has already paid off. The fact that the office heating systems are now significantly cheaper to operate thanks to the use of residual heat is an economic hit.

What alternatives were there?

Of course, we looked at other providers and technologies. One alternative, for example, was radiant ceiling technology. However, this would have required 2,500 m² of ceiling space alone. In addition, this technology was much more expensive and could not demonstrate any savings potential. In the end, KÜBLER was the provider of our choice who was able to present the best savings concept.

What can you say about the installation process?

The project went very smoothly - hard to believe considering the complexity. After all, the hybrid system was also new territory for KÜBLER. But you could tell that we were dealing with an experienced company for large-scale projects. We had a great team on site. Communication worked perfectly, there was always someone on site who could quickly and unbureaucratically find a solution when necessary. I don't think KÜBLER would otherwise have been able to complete such a large project so quickly and virtually without any subsequent improvements.

What experiences have you had in practice?

The system was installed and handed over. Since then, it has been running as planned. A constant 14 °C in all weathers. The working atmosphere has improved noticeably thanks to the even heat distribution - and the sickness rate has also fallen. What I really love is the control system. The fact that I can now operate the entire heating system from my monitor is a real benefit.

H.Y.B.R.I.D. is considered the most efficient solution from KÜBLER. Have your expectations been met?

For us, H.Y.B.R.I.D. is not only the most efficient solution from KÜBLER, but also the best concept we have come across. In every aspect: consulting, implementation, operation and, of course, the savings. An additional cash flow of almost 200,000 euros is a warm shower for any company - especially in times of crisis. Our expectations have been more than fulfilled.

H.Y.B.R.I.D.: Three components - 108 percent firing efficiency

H.Y.B.R.I.D. is the sum of the three components residual heat utilization, infrared heating and digital control - the latest and most efficient heating concept from KÜBLER to date. H.Y.B.R.I.D. combines infrared heating technology with conventional hydraulic hot water heating. The basis for this is provided by the residual heat utilization O.P.U.S.X. The innovative heat exchanger system enables the recovery of up to 15 percent of the energy that was previously lost with the waste heat from infrared heaters. With virtually no additional consumption costs, this recovered energy can be used for hot water-based heating of adjacent offices or hot service water. Other possible applications are, for example, in the area of (fresh) air heating. H.Y.B.R.I.D. thus sets new standards for the economical heating of halls: the overall system increases the combustion efficiency to up to 108 percent.

Project data

The KÜBLER Group

KÜBLER GmbH is an internationally active group of companies. Our core business is the development and production of highly efficient premium technologies for energy-saving hall heating. With an exceptionally wide range of products for almost all types of halls and room environments. KÜBLER is regarded as a pioneer and innovation leader in modern infrared heating technology.

Our products and development work regularly receive awards. The national and international awards include the Federal Prize for Outstanding Innovative Achievements from the Ministry of Economic Affairs, the Bavarian State Prize and the German Sustainability Award. KÜBLER received the highest German award for sustainable entrepreneurship in the category "Germany's most sustainable product" for the special energy efficiency of the H.Y.B.R.I.D. system.

In 2018, KÜBLER was honored for the third time with the Innovation Award of the State of Rhineland-Palatinate. Awarded for the innovative WÄRME 4.0 strategy - the digital hall heating system. Founded in 1989, the group of companies employs over 120 people and is one of the leading companies in the industry in Europe with locations in Ludwigshafen, Dresden, Hagen, Hamburg, Prague (Czech Republic), Fegyvernek (Hungary), numerous foreign agencies and a nationwide service network.