Six mistakes you should avoid when planning heating systems for new hall construction

Now more than ever, hall heating has an impact on a company's profitability and freedom of action. Why? Because energy prices are rising and environmental regulations are becoming stricter. But which heating solution is the most energy-efficient and future-proof? Companies don't have much room for experimentation. Once installed, heating systems usually remain in operation for up to 20 years. This makes it all the more important to invest a lot of time in heating planning before investing. A phase in which you should avoid the following mistakes.

Mistake no. 1: Only superficially studying the relevant laws for new hall construction

Laws are generally complex. A superficial study can become a pitfall here. This also applies to the new Building Energy Act (GEG), which has been in force since November 2020. Although it simplifies and summarizes the previous legislation - namely the Energy Saving Act (EnEG), the Energy Saving Ordinance (EnEV) and the Renewable Energies Act (EEWärmeG) - it often confuses companies. For example, many managers assume that they can only use renewable energy when building new halls. This is a fallacy that restricts the choice of technology. And often leads to compromises that are demonstrably too expensive - both to purchase and to operate. A closer look reveals this: Hall operators do not have to use renewable energies for decentrally heated zones with ceiling heights of over four meters. They can also use gas-powered infrared heaters, provided their efficiency and energy efficiency are high enough.

Mistake no. 2: Treating a hall like an office building

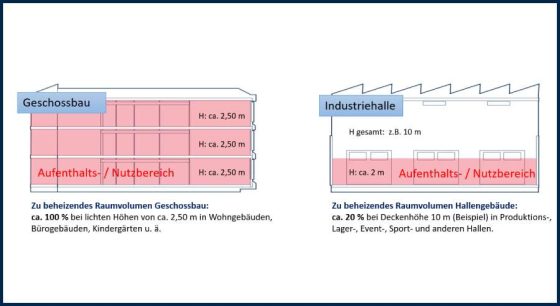

Offices are generally well-insulated rooms with low ceilings. Their volume is almost identical to the usable zone. It is therefore not a waste of energy to heat the entire room. However, the situation is completely different in industrial and commercial buildings. Anyone using the heating approach for multi-storey buildings is wasting heat and money. This is because it is usually sufficient for the working area to be warm. As a rule, this means the lower two meters of the hall - in the case of a hall with a ceiling height of ten meters, only 20 percent of the room volume. Or even just the part where people are working.

With such a targeted heating approach, the following principle applies: the smaller the ratio between the usable area and the total volume, the more important the quality of the heat transfer. Infrared heaters achieve a high level of quality here. Instead of heating the air per se, the decentralized heaters generate electromagnetic waves that are only converted into heat as soon as they come into contact with solid objects. In combination with intelligent control systems, energy savings of up to 70 percent can be achieved compared to conventional heating systems. This is a significant factor, as it can be assumed that energy will become more expensive in the coming years.

Error no. 3: Usage profile and requirements are not specified

Simply install a heating system and switch it on until it is halfway warm everywhere? Companies have been wasting energy in this way for decades. A waste that can become a competitive disadvantage in times of rising energy prices. Therefore, consider in advance what makes your new building stand out: Where exactly in the hall do employees need heat, where can it stay cooler? How much air exchange takes place in the hall and when? How much waste heat do machines and systems already produce? How can this be used intelligently?

If you know these parameters, specify requirements and create a detailed usage profile, a responsive heating system with intelligent control can adapt to the hall like a tailor-made suit. And save a lot of energy. Because the most economical heating system in terms of consumption is the one that the operator doesn't even have to switch on.

Mistake no. 4: Not using networking and intelligent control when building a new hall

Intelligent control is a luxury? Networking a superfluous gimmick? No, digitalization is essential in order to heat halls in an energy-efficient way and save a lot of money in the future. It is therefore essential to make sure that the heating system for your new building has arrived in the digital age. Networked devices, modern control systems and analysis software make it possible to adapt heating systems to the hall dynamics and thus save energy. In addition, hall operators can better meet the requirements of the DIN 50001 standard with software-supported heating systems. With this certification (or a registered environmental management system acc. EMAS Regulation), you meet the requirements for partial exemption from the EEG levy or future relief from electricity and energy tax.

Mistake no. 5: Only looking at investment costs

Focusing only on initial investment costs for decision-making? That can also be a mistake. Because much more important are the total costs that are incurred over the entire life cycle of the heating system - including service, maintenance and repair costs. A particularly interesting part of this total cost of ownership (TCO) is the consumption costs. Here you should never let the provider get away with a pi times the thumb estimate. Nowadays, it is easy to provide detailed and reliable information in accordance with DIN V 18599 - including the annual primary energy requirement, energy costs and CO2-emissions. Information that gives you planning and decision-making security.

Mistake no. 6: Not taking a close look at providers

On the way to an economical heating system for your new hall construction, you should not only take a close look at the quality of the devices, but also at the competence of the manufacturer. Research whether the company can provide credible references. Equally important: To avoid long downtimes, you should make absolutely sure that the provider will still be offering services and a spare parts supply in fifteen years' time. After all, it is annoying if you are left to your own devices to maintain your hall heating system after just a few years. You can also find out whether the company has its own research and development department. Such a department - especially in combination with convincing references - is usually a reliable indicator of competence and experience. Two points that are important for finding and operating an economical and future-proof hall heating system.

-

How is energy used correctly? What does efficiency mean? In the German government's current energy policy, there is a huge gap between aspiration and reality. After all, industrial buildings are not treated as industrial buildings because they only account for two percent of buildings - even though they are responsible for 15 percent of greenhouse gas emissions. The latter has not played a role to date. Behind this two percent are 420,000 to 480,000 hall buildings that are used in industry, commerce and municipalities as production halls, logistics halls, workshops, sports halls or sales outlets. A small number that is responsible for a significant proportion of energy consumption and GHG emissions in Germany.

-

If you are reading this article, you are probably looking for an efficient way to heat your industrial or commercial building. During your research, you have already come across one or other technology such as dark radiant heaters or hot air. Now you want to know why dark radiant heaters in particular are repeatedly highlighted as especially efficient. We'll tell you!

-

The metalworking company "Die Kanter & und Schlosser" heats its new building variably with electricity, hydrogen or gas thanks to the world innovation from KÜBLER in Ludwigshafen.

-

The horrendous rise in energy prices, the fear of Putin stopping supplies, the demand for renewable energies to combat climate change - all of this is currently causing a great deal of uncertainty. Is it still worth investing in gas-powered industrial heating systems? The answer to this question is important. Because it determines how quickly trade and industry will make their contribution to the energy transition. And how well it will be possible to meet the future requirement of climate protection in an economically viable way.