Amendment to the Building Energy Act: Saving energy is only possible by differentiating between buildings - industrial buildings are not daycare centers

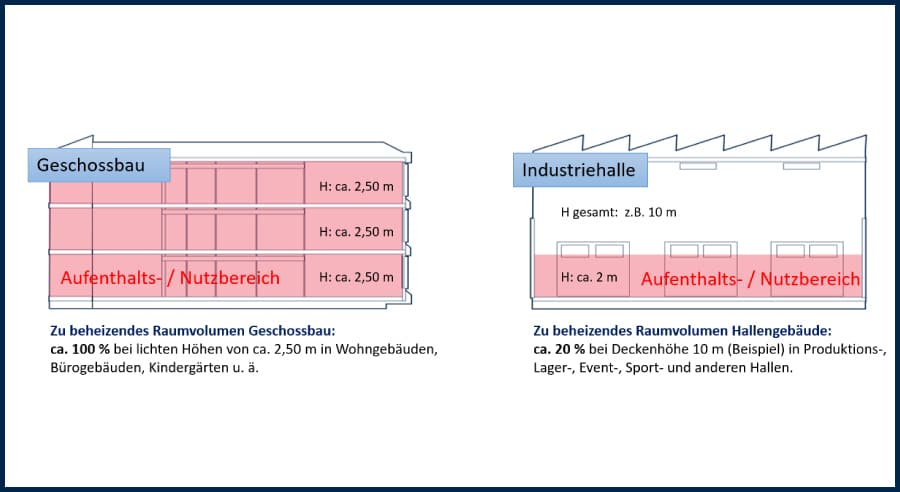

It is obvious that there is enormous potential for saving energy in these hall buildings. With ceiling heights of 4 to 40 meters and areas of up to 10,000 square meters, their room dimensions cannot be compared with apartments, offices or daycare centers, which are usually built as multi-storey buildings with clear heights of around 2.50 meters. This also applies to the heating of such room colossi - it is much more demanding than in the much lower multi-storey buildings. However, this differentiation is currently hardly taken into account in the Building Energy Act.

"If such large rooms are to be heated in an energy-efficient manner, very special technologies are required. It has rarely been as urgent as it is today, utilize all technological resourcesthat are available to us to effectively counter the energy crisis," says Thomas Kübler, founder and managing partner of KÜBLER GmbH in Ludwigshafen. He is a proven expert in heating industrial halls.

Kübler says: "Efficient heating is about providing heat with as little loss as possible in the areas of the hall where people work and need heat. As a rule, this is not at a ceiling height of 10 or 20 meters, but in an area around 2.00 meters above the hall floor."

The efficiency of special hall heating technologies can be seen in energy-efficient refurbishment projects for industrial halls.

Up to 70 percent realized savings are not an isolated case in practice.

This already relieves the financial burden on companies with cost savings of several tens or even hundreds of thousands of euros per year, depending on the size of the project. The greenhouse gas reductions are correspondingly high. This enormous reduction in energy consumption makes a major contribution to achieving the necessary climate targets.

Appropriate technologies such as decentralized infrared hall heating systems could open up around 50 percent savings potential, i.e. around 65 TWh (65,000,000,000 kWh). With a CO2-share of 0.247 kg /kWh, this would correspond to around 16,055,000 tons of the greenhouse gas CO2.

If, in turn, only half of the relevant hall buildings were to be refurbished in terms of plant technology, the CO2-reduction is still around 8 million tons - a major step towards efficiency and climate targets. This potential is relatively easy to exploit due to the available technologies, a manageable number of decision-makers and the good economic aspects for the industry such as costs, ROI and return on investment.

However, it currently appears that these highly efficient hall heating technologies are being slowed down. Under pressure from the gas crisis caused by the Russian war in Ukraine and the climate targets it has set itself, the German government is banning the installation of gas-powered heating systems across the board from 2024, for example. In addition, the funding opportunities for gas hybrid heating systems were removed virtually overnight.

Kübler says: "These decisions have caused a great deal of uncertainty among those responsible in industry and commerce and also ignore the physical reality of buildings. This is because decentralized infrared heating technologies often represent a major challenge under the demanding conditions of hall buildings. the only ecologically, economically and functionally sensible option of the heat supply."

The promotion of heat pumps in multi-storey buildings (residential buildings and non-residential buildings such as offices, restaurants, kindergartens and hospitals) is an effective lever for the energy transition. However, this sector is already suffering from the scarcity of resources. To achieve the policy targets, 2,000 heat pumps would have to be installed every day.

"In addition to a lack of material availability, there are also not enough houses suitable for heat pumps in existing buildings and we are facing a major shortage of personnel in the skilled trades. Unfortunately, only a small proportion of the existing tradespeople are qualified to install heat pumps. There is a huge gap between policy and reality here," says Martin Oldeland, Deputy Chairman of the German Working Group for Environmentally Conscious Management (B.A.U.M.)

"In addition to availability, heat pumps also have the disadvantage that they can hardly play to their strengths in industrial buildings," says Kübler.

The use of heat pumps is in the renovation area of halls hardly possible.

After all, who could clear entire production halls or warehouses, including machinery, in order to install underfloor heating associated with heat pumps in the floor? The use of hot water-based heating technologies is also not very functional in new hall construction. In contrast to decentralized IR heating systems, hot water systems have the major disadvantage of not being able to effectively meet the frequently changing, locally and temporally variable heat demand in these buildings due to their inertia. For example, during shift operation, when the doors are open, when heating individual work areas (e.g. order picking in logistics halls) or when heating individual courts, for example in indoor tennis courts. Kübler says: "As useful as heat pumps are in residential and multi-storey buildings, they lag behind the weather in indoor buildings".

How can the great efficiency potential of decentralized hall heating technologies be used in the industry?

According to experts, everything stands and falls with the recognition of halls as a separate building category, which places special demands on heating technology and therefore requires suitable, special technologies. Among the most efficient of these are modern hall heating systems such as infrared dark radiators, which are operated with natural gas, liquid gas or biomethane mixed with green hydrogen - often with impressive savings of 30 to 70 percent (see above). The currently possible certification of 20 percent H2-The leading manufacturers have already added this amount. Under laboratory conditions, 80 percent is possible without any problems. 100 percent will be achieved with retrofit kits in the next few years. Modern decentralized infrared heating systems can not only use waste heat from heating systems via condensing boiler technology, they also incorporate waste heat from production processes, for example from compressors or hardening furnaces. Fully digitized, their efficiency can be monitored across the entire heating process and documented in certified energy management systems. The user-friendliness of these modern solutions is exemplary.

Another piece of good news is that these high-efficiency systems no financing problem.

This is because the hall heating can be rented. The cost savings resulting from the reduced energy consumption are usually so high that they not only compensate for the rental price, but also leave money for the company at the end of the day. The rental model therefore makes it possible to use modern efficiency technologies without having to invest - and, incidentally, without depreciation costs - and also generate a positive contribution margin. An attractive means of perhaps still achieving the long sought-after and as yet unattained refurbishment rate of 2 percent.

-

According to the IMD Competiveness Ranking 2024[1], our once leading industrial nation has slipped from 6th to 24th place in just ten years. 45 percent of industrial companies with high electricity costs are planning or implementing plans to reduce their production or relocate it abroad. And the trend is rising[2]. Increasing bureaucratic costs and the extremely high level of energy prices in our country are causing many companies to [...]

-

The search for suitable optimization potential in energy-related processes in industrial and commercial companies is not always easy for energy management. Especially as measures in efficiency technologies and renewable energies cost money and the budget is often lacking. Many - ecologically and economically important - measures then fall by the wayside. But does that have to be the case?

-

In 2021, the new CO2-tax came into force. It is intended to help Germany achieve its climate protection targets. Read on to find out what this means for your company in terms of costs and what you should do now!

-

ESG stands for Environmental, Social and Corporate Governance and refers to the three key areas of sustainable corporate management: environment, social affairs and corporate governance. But what does this have to do with you and the way you heat your production halls and warehouses?